When it comes to precision alignment, expertise matters just as much as the equipment. In industries where uptime, safety, and long-term reliability are non-negotiable. The difference between a traditional alignment vendor and a specialized partner like ACQUIP becomes clear. We don’t approach alignment with a one-tool mindset. Instead, we combine field-proven methods, advanced metrology technologies, and equipment flexibility to deliver solutions tailored to each machine, each turbine, and each real-world constraint.

This measurement-first philosophy is what sets ACQUIP apart.

1. We Choose the Right Method, Not Just the Most Common One

Most traditional alignment vendors rely heavily on laser shaft alignment systems. And for many applications, that’s the right choice: lasers deliver fast, accurate shaft-to-shaft alignment and are ideal for standard motor-pump trains or new equipment installations.

But not all alignment challenges can be solved with a laser.

ACQUIP takes a method-agnostic approach. When a turbine requires internal diaphragm alignment or when shaft access is restricted, we deploy the ERAG/CAT (Electronic Radial Alignment Gauge / Concentricity Alignment Tool). Unlike conventional processes, the ERAG allows us to measure diaphragm misalignment with the rotor still in place, eliminating the need for tight-wire setups or intrusive disassembly. This capability makes a dramatic difference in outage efficiency, accuracy, and cost.

In short:

Traditional vendors lead with their tool. ACQUIP leads with the problem, and solves it using the method that fits best.

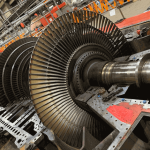

2. We Specialize in Turbines and Complex Rotating Equipment Services

Where many alignment providers focus on standard industrial rotating assets, ACQUIP was built around power generation, heavy rotordynamics, and multi-stage machines. This means our team is deeply trained in the realities of:

• Internal turbine diaphragm alignment

• Thermal growth and dynamic movement study

• Reciprocating Compressor Alignment

ACQUIP is recognized for its accurate, professional expertise and timely execution, supporting clients during outages, specialized annual services, and offsite technical assistance.

When a turbine outage reveals geometry issues, rubs, movement discrepancies, or stage-to-stage alignment problems, ACQUIP brings decades of specialized, turbine-focused experience. That specialization allows us to solve problems traditional “laser-only” vendors simply aren’t equipped to handle.

3. We Don’t Just Align, We Deliver Full-Stack Metrology

Alignment is only part of the picture. ACQUIP integrates advanced measurement technologies into our services, including:

• Laser tracker measurements

• CMM and portable arm metrology

• Dimensional verification

• Thermal growth analysis

By combining alignment data with real geometric modeling, we reduce rework, improve accuracy, and give clients confidence that corrective moves will perform as intended under real operating conditions.

This level of metrology-integrated service is far beyond what traditional alignment vendors typically provide.

4. Equipment Flexibility, Not One Tool for Every Job

Another major difference? ACQUIP doesn’t rely on a single product line or instrument.

Instead, we operate a diverse fleet of professional-grade equipment, including:

• Rotalign, Optalign, Easy laser, Permalign, and Cardan Shaft Alignment Bracketing systems

• Polyworks, SpatialAnalyzer, CAM2 Measure 10, and FARO Scene Software tools.

• Magie Magnetic Base For Curved and Flat Surfaces

• Custom Premade Turbine Alignment Shims

… A complete inventory available for rental, included in our services based on the project needs.

This flexibility ensures we always deploy the right tool for the alignment scenario, not simply the tool we sell or the one a technician prefers.

For our clients, this means:

• Better fit to the job

• Better accuracy

• Access to specialized tools without long-term capital expenditure

5. Proven Field Procedures Backed by Real Engineering

Precision instruments are only as effective as the procedures behind them. ACQUIP has developed structured, repeatable alignment workflows, from shaft alignment to ERAG readings and internal turbine checklists.

Our procedures are built on:

- Industry standards

- OEM recommendations

- Thousands of hours of real outage experience

This eliminates guesswork and ensures every measurement, correction, and verification follows a methodical, validated process.

Traditional alignment vendors frequently rely on generic “point-and-shoot” laser workflows. ACQUIP combines formal procedures with deep mechanical understanding to deliver repeatable, defensible, and technically sound results every time.

The ACQUIP Difference: Precision Without Assumptions

Traditional alignment vendors bring a tool. We bring a strategy.

Every unit, every turbine, every shaft train has a different mechanical reality, so we match the method to the machine. With ACQUIP you don’t just get alignment services; you get a technical partner who understands how your equipment behaves, how geometry influences performance, and how to ensure reliability for the long run.

Ready to Solve Your Alignment Challenge?

If you’re facing alignment issues, whether simple or highly complex, ACQUIP can help you choose the right method, the right measurement, and the right path to reliable performance.

Contact us today for a customized alignment and metrology assessment.

FOLLOW US

REQUEST A QUOTE

ADVANCED SHAFT ALIGNMENT TRAINING EBOOK