Leica Absolute Tracker ATS600 accuracy

The first ever direct scanning laser tracker

Why Leica Absolute Tracker ATS 600?

A large number of manufacturers are interested in digitally locating and examining huge parts and surfaces that are just outside the reach of a handheld, conventional 3D laser scanner, touch probe, or reflector. The Leica Absolute Tracker ATS600 is equipped with a novel operating concept that enables metrology-grade accuracy in locating a point in 3D space without requiring a reflector at the measurement site, making it capable of handling the demands of these new applications.

The first-ever Scanning Absolute Distance Meter, a metrology-grade version of this technological principle, powers the ATS600 and can locate a point to within 300 microns from as far away as 60 meters. This device is based on the well-established wave-form digitizer technology that powers several high-end surveying tools.

The ATS600 can quickly generate a measurement grid defining the target measurement surface by measuring a succession of such points throughout a user-definable measurement region. Additionally, the density of that point grid may be altered, giving the operator total control over how much detail and process speed to transmit into your metrology program.

With the Leica Absolute Tracker ATS600, one person can quickly do 3D analysis on items that used to take a lot of time to digitize or that were too big to measure in a useful way. The world’s first “direct scanning laser tracker” is about to change the way we think about 3D measurement in a big way. This will allow productive quality control to reach completely new areas of production.

This tracker also offers complete Power Lock functionality and reflector measurement at a distance of up to 80 meters, as well as many other features that are common to the rest of our Absolute Tracker product line. When measuring on a large scale, using both reflector measurements and direct scanning gives you great performance all around. You can use individual reflector readings for alignment and feature definition, and you can quickly scan for surface description.

Applications of the TRACKER

Since the launch of the Leica Absolute Tracker ATS600, the system’s ground-breaking direct scanning capability has opened a wide range of new metrology-grade inspection applications; measurements that were previously unfeasible can now be carried out with ease, allowing for greater quality control over large-scale products than ever before possible.

Now, the exceptional accuracy of the Leica Absolute Tracker ATS 600 makes it a versatile tool across various industries:

- Aerospace: In aerospace manufacturing, where components must meet stringent tolerances, the leica ats600 accuracy is invaluable for quality control and ensuring the integrity of critical parts.

- Shipbuilding: Shipbuilding is one of many industrial applications. Reliability and capacity to operate at the vast scales needed for shipbuilding are prerequisites for an accurate inspection that guarantees the ship stays straight and does not bend as a result of minor manufacturing process defects.

- Automotive: Precision is paramount in automotive manufacturing, and the leica ATS 600 accuracy excels in providing precise measurements for components, assemblies, and alignments.

- Heavy Machinery: The tracker’s sub-millimeter of the leica ats600 accuracy is particularly beneficial in the manufacturing and alignment of large and complex machinery where precise measurements are essential.

Elevated temperature quality inspection

In new production areas, the Leica Absolute Tracker ATS600 is saving time and raw materials thanks to its metrology-grade selective scanning at up to 60 meters.

Investing in a measurement device that can guarantee the forged part is as near to the intended dimensions of the final product as feasible makes sense when it comes to forging huge components. On the one hand, if extra machining is needed to bring the raw forged item within design tolerance, a large forging may result in a major loss of labor and material. Conversely, an undersized forged part presents an even bigger challenge as, if it is not big enough in any one dimension to fit the final part’s design, the entire piece could have to be destroyed. Naturally, this leads to an even bigger loss of resources and time.

The obvious solution to this problem is dimensional inspection, but this is a challenging procedure when high temperatures are involved since standard metrology instruments cannot endure the 1000°C temperatures that are seen during the forging of massive metal parts.

This issue can be resolved with the help of the cutting-edge Leica Absolute Tracker ATS600 laser tracker, thanks to its long-range direct scanning capability. With the use of a capability called “direct scanning,” a tracker can measure spots on a surface up to 60 meters away with an accuracy of tenths of millimeters.

The tremendous temperature is not an issue for the ATS600 at this distance from the heated component, and parts can be directly forged to a size much closer to the final needed dimensions than is usually achievable, thanks to accuracy on glowing-hot parts maintained at sub-millimeter levels.

Direct scanning functionalities

This laser tracker’s exclusive feature is the ATS600’s direct scanning capability. It is comparable to the hemispherical scanning used in surveying by terrestrial laser scanners, but with much higher accuracy and the capacity to selectively scan smaller measurement areas instead of gathering data for a large area that needs to be filtered afterwards. The ATS600 can also get results quickly because it works with common metrology software protocols that let you directly compare actual and nominal dimension data.

The new direct scanning approach increases repeatability and precision. The special needs of aerospace customers led to the creation of an innovative new measuring method for direct scanning with the Leica Absolute Tracker ATS600.

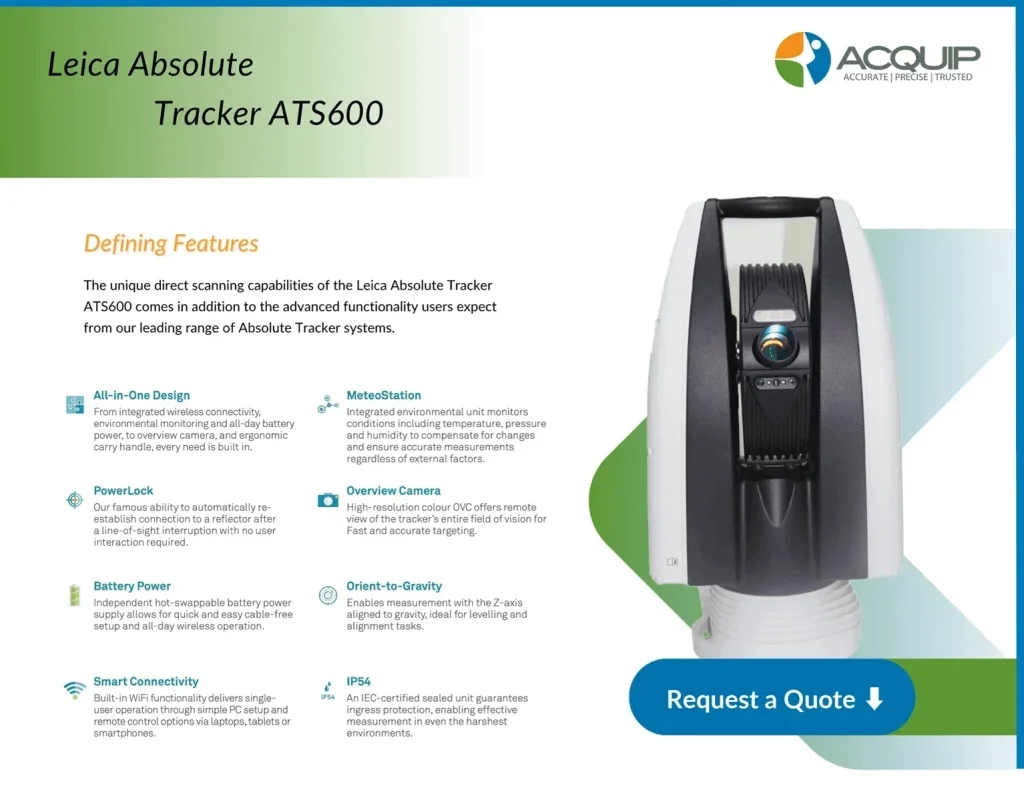

See the Leica Absolute Tracker Key features and benefits

Conclusion

The Leica ATS 600 accuracy is a testament to the commitment to excellence in industrial metrology. Whether in large-scale manufacturing or intricate quality control processes, the ATS 600 stands out as a reliable and accurate solution, empowering professionals to achieve uncompromised precision in their work.

This level of accuracy not only ensures the reliability of measurements but also contributes to the overall efficiency and quality of the manufacturing and metrology processes where the ATS 600 is deployed.

View more

Leica ATS600 Absolute Tracker + MAGIE

FOLLOW US

Request a Quote

ADVANCED SHAFT ALIGNMENT TRAINING EBOOK