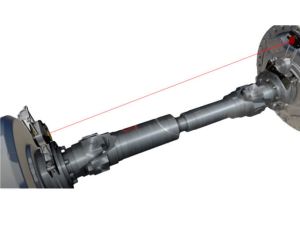

Cardan Shaft Alignment Overview

Cardan shafts, also known as universal joints, are engineered to connect non-linear shafts, compensating for any offset between the driver and driven components. This design allows for the transmission of torque and rotation while accommodating variations in shaft angles.

Importance of Alignment:

Despite their flexibility, Cardan shafts have limitations, particularly when it comes to large angular misalignments. Substantial misalignments can lead to increased vibration, affecting the efficiency and lifespan of the machinery. To counteract this, precision alignment is essential.

Key Alignment Considerations/rules:

1. Offset Compensation:

- Recognize how Cardan shafts excel at compensating for offset between shafts, enhancing their versatility.

- A Cardan Shaft is good for Offset misalignment only, not angle misalignment.

2. Misalignment in either vertical or horizontal plane:

The offset misalignment that is entered has to either be in the vertical or the horizontal plane. It cannot be in both.

4. Angle present at each knuckle should be the same: The angle that is presented at each one of the knuckles in the Cardan Shaft has to be the same.

5. Angle at knuckle should not exceed 3.5 degrees: The angle that is presented at the knuckles should not exceed 3.5 degrees.

6. Alignment Tools:

- Explore advanced alignment tools, such as laser alignment systems, designed to streamline and enhance the alignment process.

These are some options available for Cardan Measurement:

Rotalign Systems

Cardan Shaft Alignment Bracketing

Step-by-Step Alignment Procedure using a shaft alignment system & cardan shaft alignment:

1. Pre-Alignment Checks:

- Before diving into the alignment process, conduct thorough checks on the equipment, ensuring that all components are in good condition.

2. Positioning the Equipment:

- Properly position the machinery or equipment, making sure it is securely mounted and supported to avoid any shifts during the alignment process.

3. Checking Angular Misalignment:

- Measure and assess the angular misalignment between the connected shafts. This is a critical parameter for Cardan shafts.

4. Adjustments and Corrections:

- Based on the measurements, make adjustments to correct any misalignments. This may involve tweaking the positioning of the shafts or modifying the joint angles.

Conclusion:

In the realm of Cardan shaft alignment, understanding and adhering to tolerances are non-negotiable. This precision not only safeguards your machinery but also contributes to enhanced efficiency and longevity. As you embark on alignment endeavors, keep a keen eye on the specified tolerances, for within these boundaries lies the key to optimal performance.

Featured Resource

Learn about Alignment Double Cardan Shaft check procedure.

Alignment Check

– Double Cardan Shaft

FOLLOW US

Request a Quote

ADVANCED SHAFT ALIGNMENT TRAINING EBOOK